Project Description

FLEXI BURN: Development of high-efficiency CFB technology with CCS

This project combines the CFB’s intrinsic advantages (fuel flexibility and low emissions) with oxygen-firing for carbon capture and storage (CCS). In oxygen-firing systems the fuel is burned in a mixture of pure O2 and recirculated flue gas instead of air. The absence of air nitrogen produces a flue gas stream with a high concentration of CO2, making it much easier to separate the CO2. CFB technology appears to be ideally suited to oxygen-firing combustion. The project aims to develop and demonstrate a power plant concept that allows flexible high-efficiency air-firing of fossil fuels with biomass and oxygen-firing with carbon capture which provides the potential for an almost 100% reduction in CO2. The use of the CFB technology will allow the utilization of indigenous coals and biomass with CCS thus addressing the needs for security of supply, reduction of imported coals dependency and addressing the climate change issue.

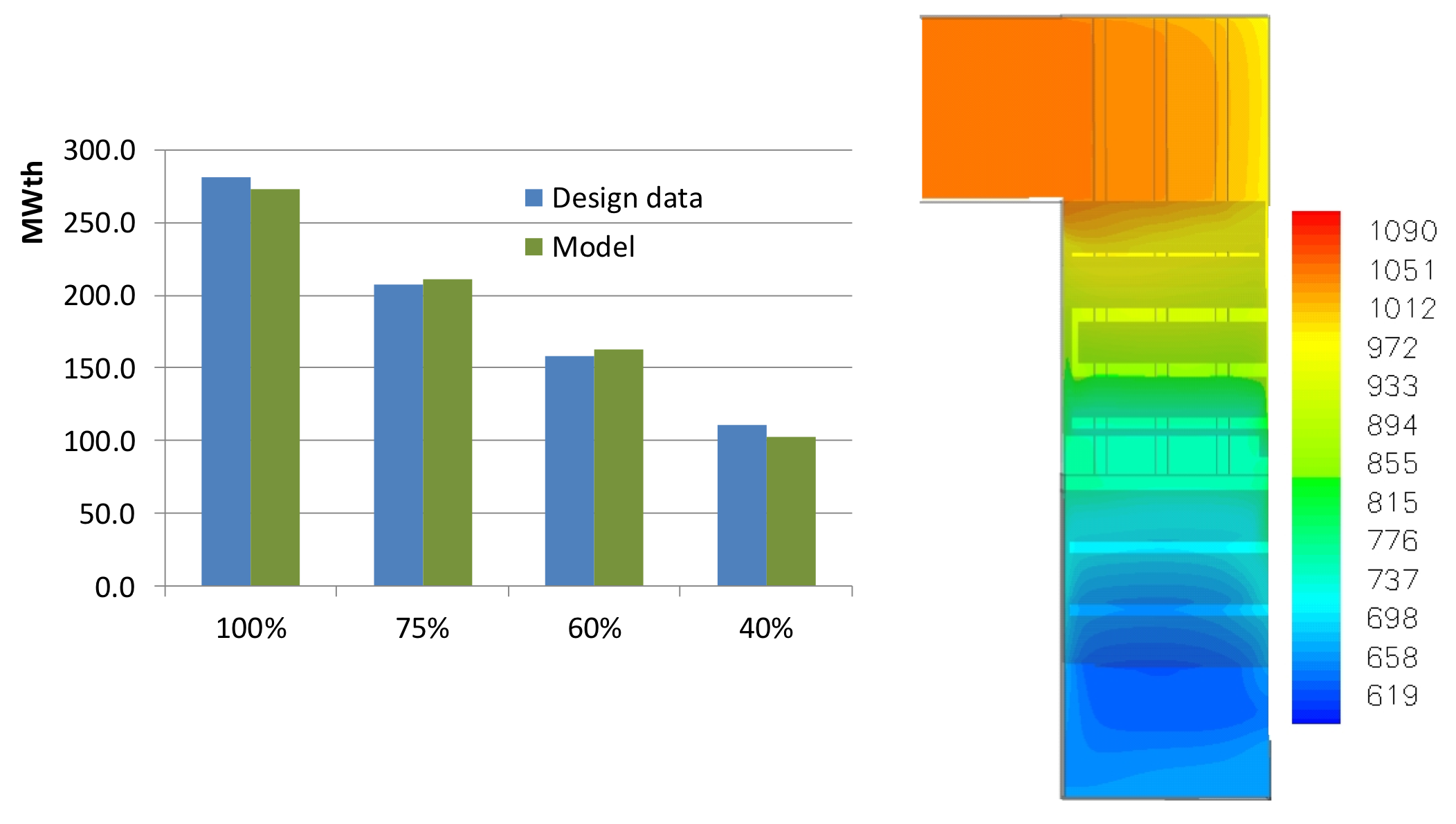

The overall result of this project will be a power plant design based on the FLEXI BURN CFB concept, ready for demonstration of high efficiency large utility-scale power plant with CCS burning a large variety of indigenous and imported coals from lignite to anthracite as well as co-firing biomass. Demonstration tests with different coals at a first-of-its-kind 30 MWth air-oxygen-flexible CFB pilot facility and validation tests at the world’s first and largest supercritical once through CFB (460 MWe Lagisza in Poland) are essential elements in the project to ensure the efficient, reliable and safe design of the commercial scale FLEXI BURN power plant.

The primary novelty of the proposed technology is in the full utilisation of all of the new CFB design and process advancements when merging a CFB boiler with a supercritical once through steam cycle and air separation unit together with CO2 capture unit for CCS. This encourages utilities to take the new technology, which has the built-in capability for CCS, into use and decommission old, inefficient and high polluting capacity with lower efficiency and emission performance. In air-firing, the high efficiency has a direct impact on CO2 emissions due to reduced consumption of fuel. In addition, by substituting 20% of coal input with renewables, CO2 emission can further be reduced by 15-20%. Furthermore, the FLEXI BURN CFB concept is capable of CCS whenever the CO2 storage is available. At a power plant with full CCS capability, the FLEXI BURN CFB concept serves as a risk mitigation tool that enables power generation during temporary outages of the CO2 transport and storage facilities. Such features are expected to facilitate investment decisions for highly capital-intensive CCS power plant projects.

FLEXI BURN: Development of high-efficiency circulating fluidized bed technology to provide flexible air/oxy operation for a power plant with carbon capture and sequestration was a European project funded by the European Union as FP7-ENERGY-2008-TREN-1. It ran from 01/09/09 to 28/02/13.

The FLEXI BURN partners were:

ENDESA GENERACION SA Spain

FUNDACION CIUDAD DE LA ENERGIA Spain

AMEC FOSTER WHEELER ENERGIA OY Finland

EDP – GESTAO DA PRODUCAO DE ENERGIA SA Portugal

Tauron Wytwarzanie S.A. Oddzial Elektrownia Lagisza Poland

PRAXAIR NV Belgium

ADAPTIVE PREDICTIVE EXPERT CONTROL ADEX SL Spain

UNIVERSIDAD DE ZARAGOZA Spain

LAPPEENRANNAN TEKNILLINEN YLIOPISTO Finland

POLITECHNIKA CZESTOCHOWSKA Poland

FOSTER WHEELER ENERGIA SL Spain